- Details

- Category: Services

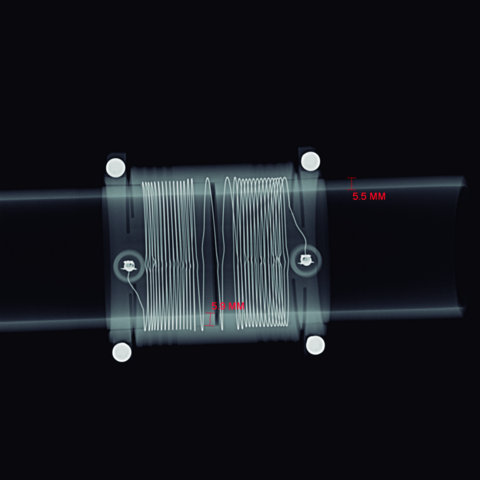

Alternating Current Field Measurement

Advanced electromagnetic inspection systems of multiple technologies, including Eddy Current, MFl. NFT, and RFT for the fabrication and in-service inspection of such units as air conditioners, heat exchangers, boilers, and super heaters are commonly used. Alternating Current Field

Method of measurements (ACFM) is also used to support the petrochemical sector.

The digital data obtained can be easily handled, which permits fast data processing using specific and proprietary software to maintain constant follow-up and comparison throughout the integrity status time and remaining life of the inspected units.